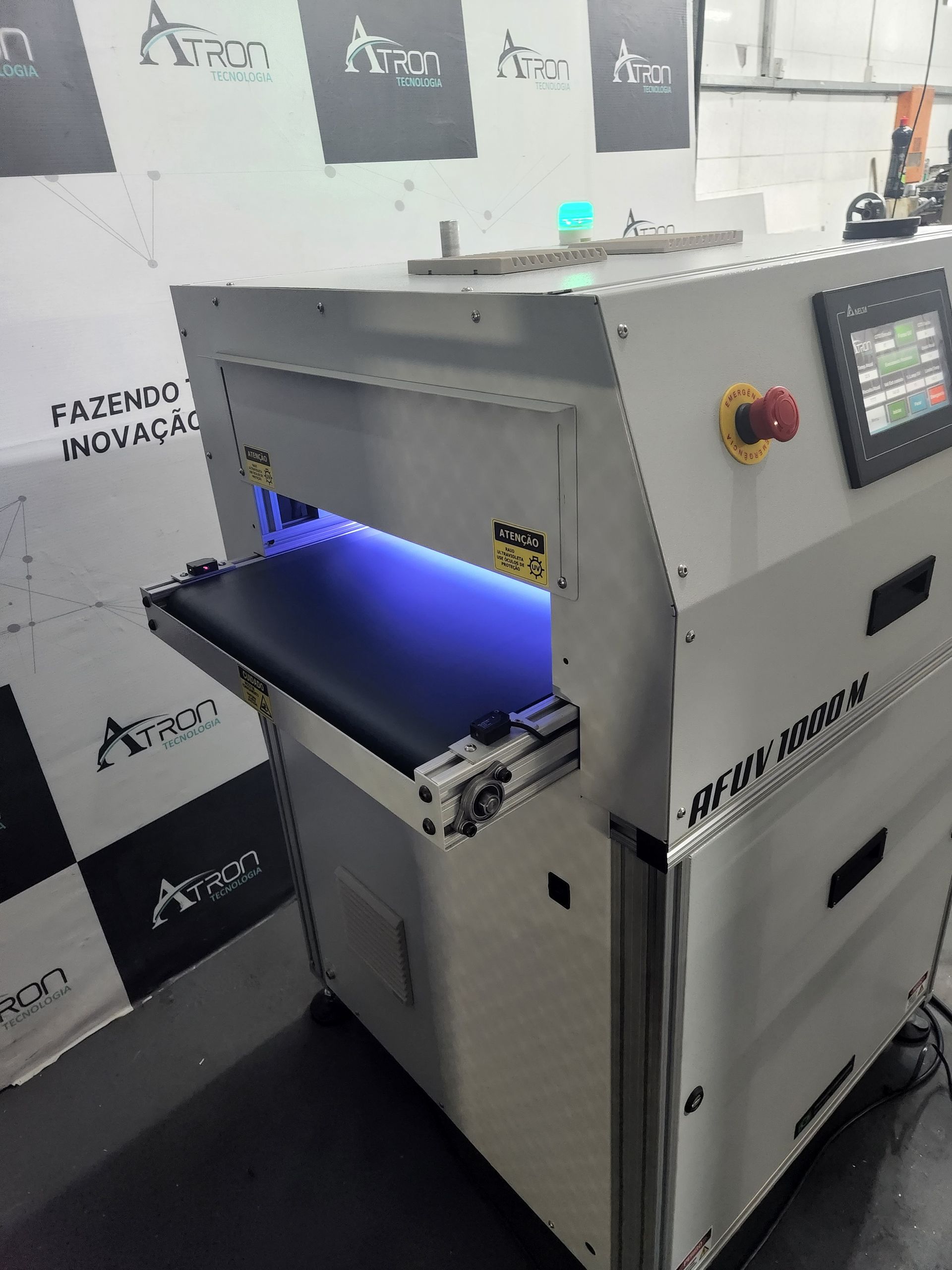

AFUV1000M - UV CURING OVEN

Description

Model: AFUV 1000M UV oven for curing resins; Suitable for medium and high production; High production performance and high process performance; National production. Description: UV oven for curing resins and conformal coating with HMI for parameterization and monitoring, with up to 02 zones, one UV zone and one IR zone. Technical assistance and training directly with the manufacturer and spare parts in Brazil.

Features

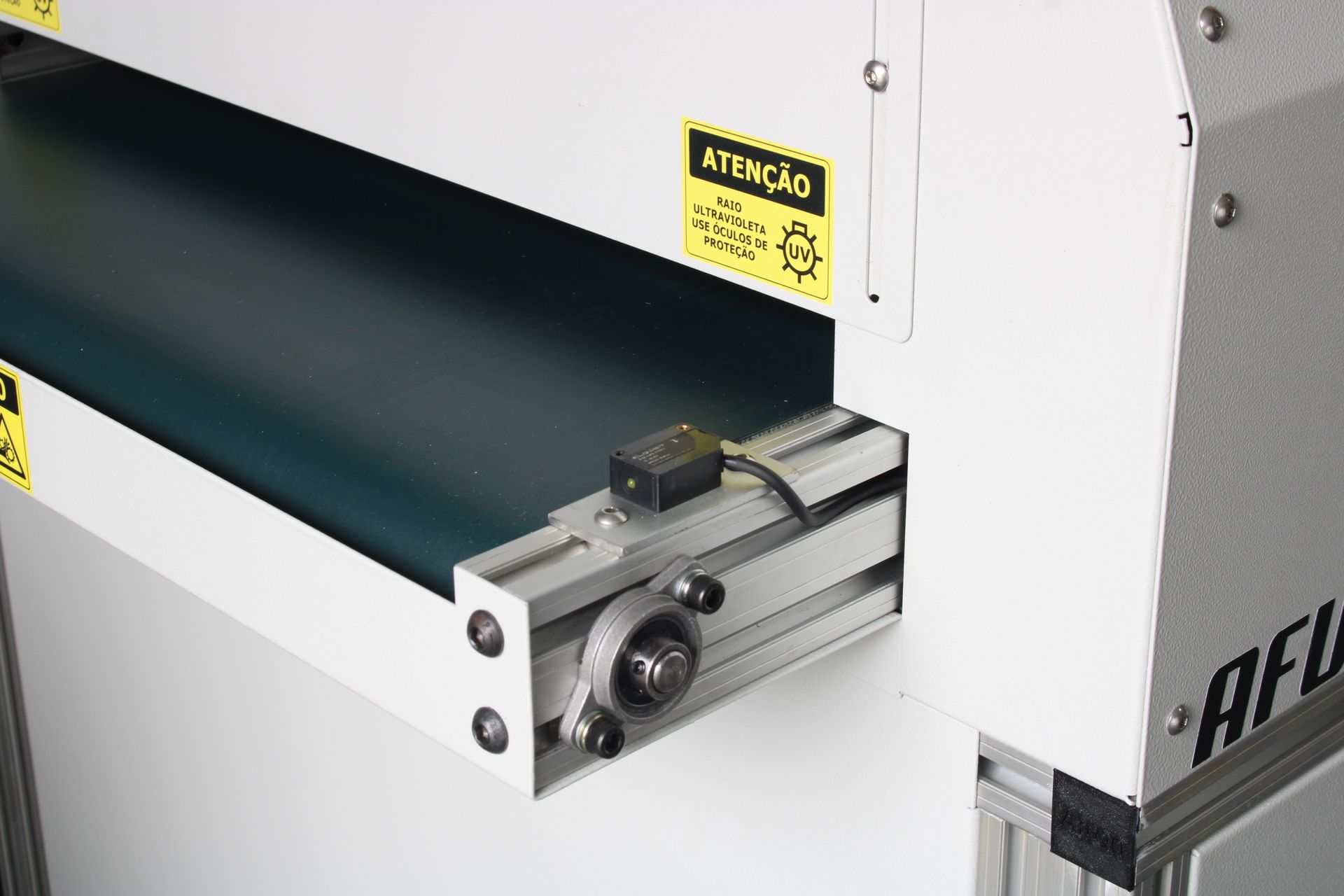

Easy and interactive control system. • HMI for parameterization and monitoring of equipment operation; • Programming of up to 10 models with different settings; • UV Zone temperature monitoring; • IR Zone temperature control. • UV Zone temperature protection system; • Exhaust system with 4" hoods and ducts; • 3" casters for movement; • USB event log and fault log.

Datasheet

1 - Model: AFUV 1000M 2 - Control Mode: Configuration/HMI 4" with PLC 3 - Equipment Dimensions: 1100mm (W) X 800mm (D) X 1600mm (H) 4 - Equipment Weight: 150kg 5 - Cabinet: High resistance epox paint Light emitting module: 6 - Type: UV Light Source - 01 - 2019102513255 7 - Lamp: High pressure metal vapor lamp HPM 15 8 - Power: 2000W 9 - Radiation: Radiation in the Diazio range (320-340NM) 10 - Base: C14X Conveyor: 11 - Conveyor: Teflon blanket 4X4 mesh (mesh belt) 12 - Dimensions: 1000X350mm 13 - Motor: Geared motor 1/4hp, reduction 1:50 Exhaust: 14 - Type: Centrifugal exhaust fan 550W/ 220vac 15 - Outlet: 4" exhaust duct Items/Accessories 16 - Conveyor speed control on HMI 17 - Board input and output sensor 18 - UV temperature monitoring 19 - Registration of up to 10 setup models 20 - UV lamp temperature protection system 21 - Event and fault log 22 - Emergency button Machine Base/Feet 23 - 3" casters 24 - Adjustable leveling feet Electrical - Power Supply 25 - Voltage: 220V - 60Hz 26 - Current: 50A

Guarantee

A) Equipment: Full manufacturer's warranty for a period of 12 (twelve) months after the date of shipment. The customer is responsible for shipping and returning parts under warranty to the manufacturer. Defects caused by improper use are excluded from the warranty. Full parts supply warranty for 10 years. B) Labor: 12 (twelve) months after the date of shipment. Defects caused by improper use are excluded from the warranty. For equipment installed outside the city of Manaus, travel and accommodation expenses for ATRON's technical personnel, incurred during the installation of the equipment, courses and technical assistance calls will be the customer's responsibility. Service Limitations: Technical services within the service warranty period will be free of charge during business hours - MON - FRI from 8:00 am to 5:00 pm. Services provided by request for a technical call outside business hours will be charged per actual working hour, regardless of the call condition. Coverage: All parts and components subject to natural wear and tear, or caused by failure or lack of preventive maintenance and conservation, or by operating errors, or by intervention by third parties not qualified or authorized by the manufacturer or supplier, are considered "out of warranty". The group of parts and components subject to wear and tear includes all units of movement, friction, constant drive and under the direct influence of an external supply source, such as compressed air, vacuum and water. The most common are: chains, guides, pulleys, toothed crowns, belts, pulleys, bearings, bushings, air filters, filters in general, lenses, nozzles, limit switches, ejector valves, solenoid valves, pneumatic pistons, among other parts that are proven to be parts and components of movement and wear. For services applied within this defined group, the technical hours used in the repair or replacement will be charged separately according to the standard technical hour table in effect at the time. Installation: It will be carried out by an ATRON technician at no additional cost to the customer, however, for equipment installed outside the city of Manaus, travel, food and accommodation expenses will be the customer's responsibility.

See more details of

UV Curing Oven

Watch the UV Curing Oven in operation directly from our factory. In the video, we present the structure and basic operation of the equipment, highlighting its finish, robustness and reliability. An ideal preview for those who want to learn about the quality of our engineering focused on industrial processes with a focus on fast and precise curing.